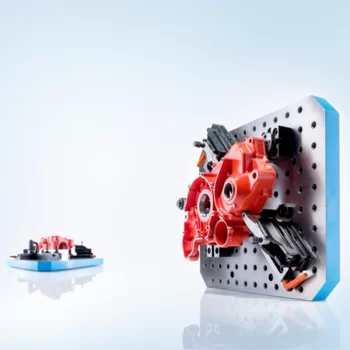

Lyftögla självlåsande, med handtag

EH 22351.

T-handtaget kan användas för att flytta eller transportera arbetsstycken för hand, t.ex. halvfärdiga komponenter, fixturer, högtalare och andra behållare.

Rost och väder-skyddad, därmed även lämplig för användning utomhus. Solid, härdad, hårdbelagd pinne med hög lyftkapacitet.

Ert urval resulterade i 4 träffar

Fler detaljer

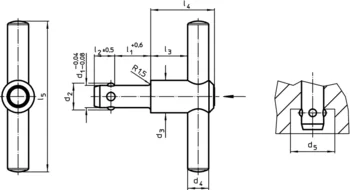

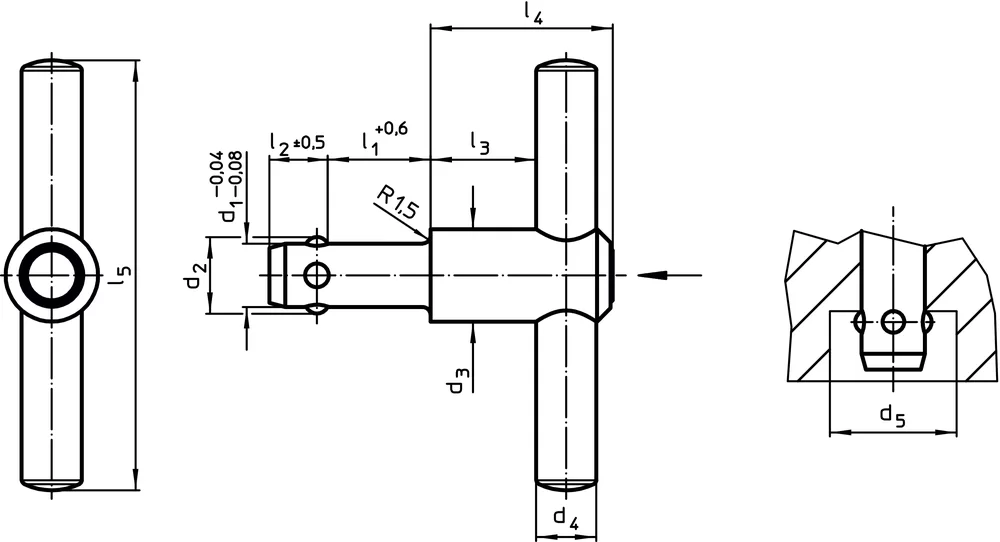

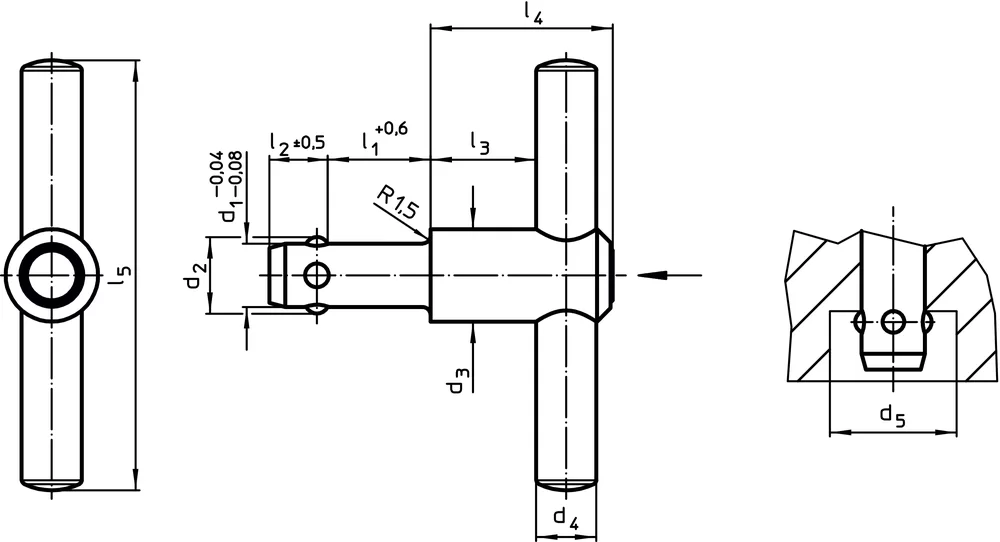

- d1 -0,04 -0,08: 8 mm

- l1 +0,6: 35 mm

- d2: 9,35 mm

- d3: 21,5 mm

- d4: 14 mm

- d5 min.: 9,85 mm

- l2 ±0,5: 8,75 mm

- l3: 18,7 mm

- l4: 36 mm

- l5: 100 mm

- Bärande kraft F1: 500 N

- Lokaliserings hål H11: 8 mm

- Operating temperature range max.: 250 °C

- Vikt: 136 g

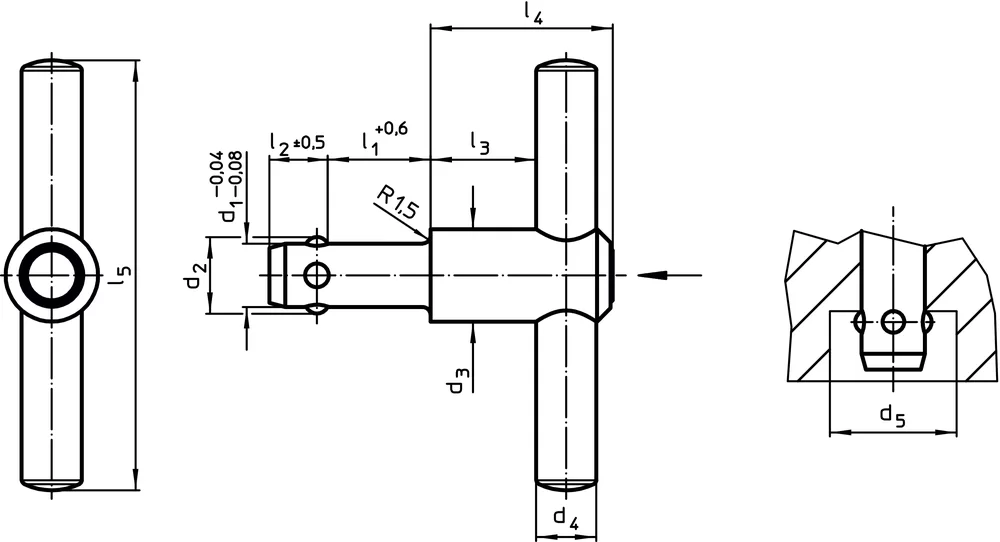

- d1 -0,04 -0,08: 8,3 mm

- l1 +0,6: 35 mm

- d2: 9,65 mm

- d3: 21,5 mm

- d4: 14 mm

- d5 min.: 10,05 mm

- l2 ±0,5: 8,75 mm

- l3: 18,7 mm

- l4: 36 mm

- l5: 100 mm

- Bärande kraft F1: 500 N

- Lokaliserings hål H11: 8,3 mm

- Operating temperature range max.: 250 °C

- Vikt: 142 g

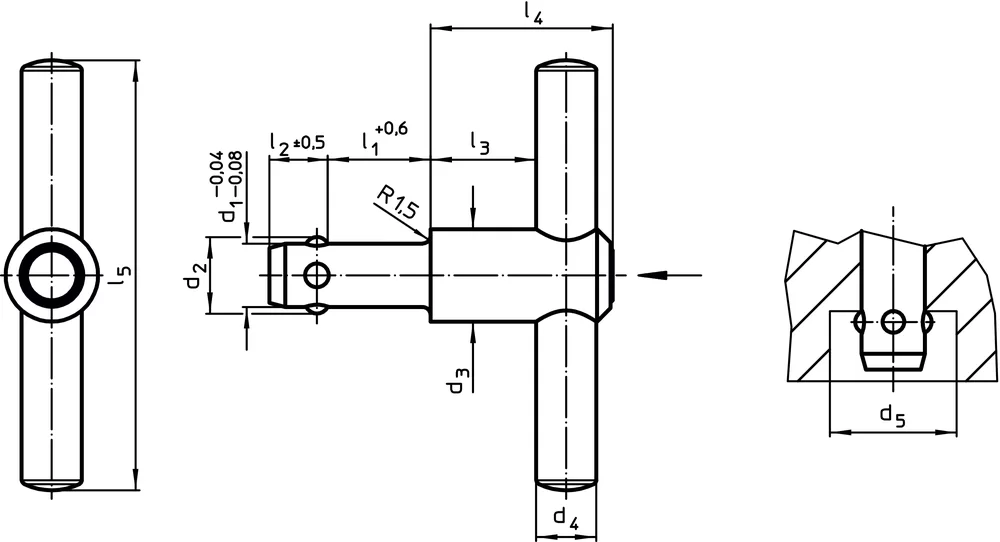

- d1 -0,04 -0,08: 10 mm

- l1 +0,6: 50 mm

- d2: 11,7 mm

- d3: 21,5 mm

- d4: 14 mm

- d5 min.: 12,2 mm

- l2 ±0,5: 10,2 mm

- l3: 18,7 mm

- l4: 36,5 mm

- l5: 100 mm

- Bärande kraft F1: 500 N

- Lokaliserings hål H11: 10 mm

- Operating temperature range max.: 250 °C

- Vikt: 154 g

- d1 -0,04 -0,08: 12 mm

- l1 +0,6: 50 mm

- d2: 14,2 mm

- d3: 21,5 mm

- d4: 14 mm

- d5 min.: 14,7 mm

- l2 ±0,5: 11 mm

- l3: 18,7 mm

- l4: 36,5 mm

- l5: 100 mm

- Bärande kraft F1: 500 N

- Lokaliserings hål H11: 12 mm

- Operating temperature range max.: 250 °C

- Vikt: 177 g

Material

Bult

- Rostfritt stål 1.4542, utskiljningshärdad

Handtag

- Aluminium, blå-anodiserat

Tryckknapp

- Aluminium, blå-anodiserat

Fjäder

- Rostfritt stål

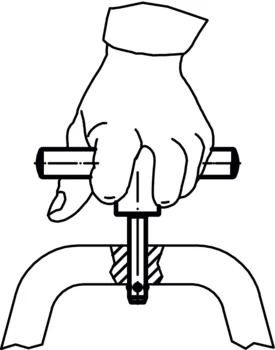

Montering

Enkla H11-borrhål är tillräckliga.

Mounting:

- Press in the button and hold it down

- Insert the lifting pin

- Release the button (The button must be back in its original position)

Dismantling:

- Press in the button and hold it down.

- Remove the lifting pin.

- Release the button.

Drift

Each lifting pin contains an operating manual. This document is also available for download as PDF.

Tillbehör

Lokaliseringsbussningar för d1 = 8, 10 och 12 kan användas som tillbehör.

Ytterligare produkter

Icke-RoHS-kompatibel

Överensstämmer inte med direktiv 2011/65/EU och direktiv 2015/863

Innehåller SVHC-ämnen >0,1 % w/w

Innehåller bly - SVHC-lista [REACH] per 23.01.2024

Innehåller proposition 65-ämnen

Bly kan orsaka cancer och reproduktionsskador vid exponering

https://www.P65Warnings.ca.gov/

Fri från konfliktmineraler

Denna produkt innehåller inga ämnen betecknade som konfliktmineraler" såsom tantal, tenn, guld eller volfram från Demokratiska republiken Kongo eller angränsande länder."

What is the difference between lifting pins and threaded lifting pins?

Components that have an existing thread can be moved or lifted with the threaded lifting pin. The lifting pins can be mounted very quickly in existing holes with undercuts. If no undercut is possible, e.g. with thin-walled parts or soft support material, an associated locating bushing can be used.

What to consider when mounting the lifting pins?

Tolerance H11 is sufficient for the locating hole. The lifting pin must always be inserted completely into the hole. As this is a TÜV-certified load lifting device with CE marking, the operating instructions must be observed.

How much axial load may be applied to the lifting pins?

The maximum load capacity depends on the variant used. The values are in the range of 1.5 kN (diameter 8) to 10 kN (diameter 20) with 5-fold safety. Lower values apply for diagonal pull or 90° pull direction - see product data table.

From which quantity can a special geometry be produced for the lifting pins?

An economical offer can be made for orders of 10 or more. Please feel free to send us your enquiry if required.

What is the difference between the TÜV certificate and the CE marking for lifting pins and threaded lifting pins?

As the threaded lifting pins and lifting pins are load lifting device and thus fall within the scope of the Machinery Directive 2006/42/EC, CE marking is mandatory. The CE marking includes, among other things, that a maximum load capacity of the lifting pins and/or threaded lifting pins is specified. This information is determined by internal calculations and tests. The lifting pin or threaded lifting pin receives a TÜV approval only if these values have also been tested and approved by the TÜV. Special designs are only manufactured as special pins without CE marking and thus without indication of the load capacity, as no tests and calculations are usually effected for them. If necessary, a CE marking can be issued if the lifting pin or threaded lifting pin is similar to a standard lifting pin and its load data can be used as a reference. A TÜV certificate must be specially ordered from the TÜV for each size and is accompanied by additional costs. Please send us your enquiry if required.

Are the details on the lifting pins an indication of the production batch?

Yes, in addition to the annual production date, the respective serial number S/N is also indicated on the lifting pin.

Of what materials are the lifting pins made?

There is a version made of heat-treated steel, tempered, manganese phosphated and a version made of stainless steel 1.4542 precipitation hardened, depending on the area of application. For load values see product data table.

What is the service life of a lifting pin?

This is not possible to answer in a general way, as it always depends on the application and the environmental influences. If a lifting pin is damaged, e.g. if it is cracked or deformed, it must be removed from use immediately. This visual and functional check must be carried out before each use. Furthermore, the lifting pin must be subjected to a safety check once a year, including a visual and functional check by a qualified person.

Can the lifting pins be used for personal protection?

The lifting pins have no approval to be used for the protection of persons. If the lifting pins should be used for this purpose, the lifting pin must be specially approved as a personnel hoist by the manufacturer of these products.