-

Products

New Products

- Locators with bore hole, for spring plungers

- Locators smooth, for spring plungers

- Holders for spring plungers

- Index Plungers Mini Indexes with mounting flange

- Index Plungers with locking mechanism push-lock

- Index Bolts threadless, weldable

- Spring Push Plungers with mounting flange, horizontal

- Threaded Lifting Pins self-locking, with handle

- Bedding Supports

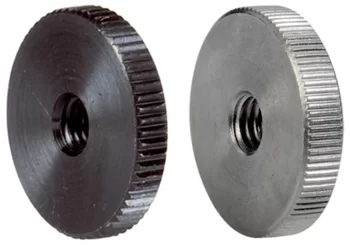

- Flat Knurled Nuts DIN 467

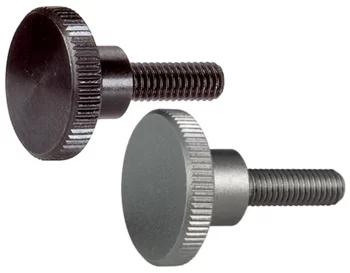

- Flat Knurled Thumb Screws DIN 653

- High Knurled Nuts DIN 466

- High Knurled Thumb Screws DIN 464

- Rubber Metal Buffers waisted

- Hinges

- Hinges

- Hinges elongated on one side

- Hinges elongated on both sides

- Hinges long version

Further Information:Product Groups- Forestry Tools

- Accessories

- Promotional Boxes

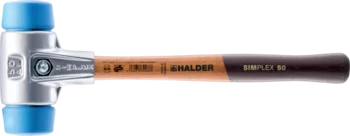

- SIMPLEX soft-face mallets, cast iron housing

- SIMPLEX soft-face mallets, reinforced cast iron housing

- SIMPLEX soft-face mallets, aluminium housing

- SIMPLEX soft-face mallets, cast iron housing, with "Stand-Up"

- SIMPLEX soft-face mallets, cast iron housing, 50:40

- SIMPLEX soft-face mallets, aluminium housing, 50:40

- SIMPLEX soft-face mallets, cast iron housing, extra short handle

- SIMPLEX soft-face mallets, cast iron housing, with "Stand-Up", extra short handle

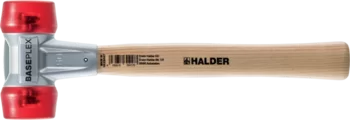

- BASEPLEX soft-face mallets

- SIMPLEX sledge hammers, cast iron housing

- SIMPLEX sledge hammers, reinforced cast iron housing

- SIMPLEX sledge hammers, cast iron housing, with "Stand-Up"

- SUPERCRAFT soft-face mallets

- BLACKCRAFT soft-face mallet

- SECURAL soft-face mallet

- SUPERCRAFT sledge hammers

- FERROPLEX Combi Hammer

New Items- SIMPLEX soft-face mallets, 50:40 TPE-soft / TPE-mid; with cast iron housing and high-quality wooden handle

- SIMPLEX soft-face mallets, 50:40 TPE-soft / TPE-mid; with aluminium housing and high-quality wooden handle

- SIMPLEX insert, 50:40 TPE-mid, grey

- SIMPLEX Plus Box Starter Kit SIMPLEX soft-face mallet D60, rubber composition with "stand-up" / superplastic as well as one TPE-soft and one TPE-mid insert plus bottle opener

- SIMPLEX Plus Box Starter Kit SIMPLEX soft-face mallet D80, rubber composition with "stand-up" / superplastic as well as one TPE-soft and one TPE-mid insert plus bottle opener

- SIMPLEX Promotional Box Automotive SIMPLEX soft-face mallet D40, copper / soft metal plus puncher

- BLACKCRAFT Promotional Box Automotive BLACKCRAFT soft-face mallet D60 plus Magnetic Holder

- Promotional Box Dreamteam Door and Window Construction SIMPLEX soft-face mallet 50:40, TPE-soft / TPE-mid and SECURAL plus soft-face mallet

- Service

- Newsroom

- Company

- Contact

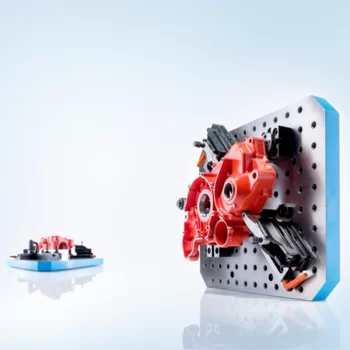

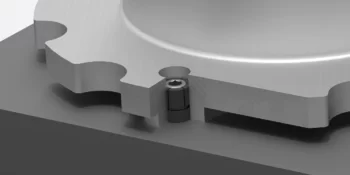

23340.0512 - Centering Clamping Mandrels

cylindrical

The centering clamping mandrels, cylindrical are ideal for use in fixture construction. They enable workpieces to be clamped with a hole on their inside diameter and therefore without interfering clamping edges. The centering clamping mandrels can be mounted on grid and fixture plates, for example, by pressing them into bores or screwing them into threads.

They enable exact positioning, offer precise repeat accuracy and achieve high holding forces when clamping parts with holes. The centring clamping mandrels offer the possibility of fixing complex workpieces without external clamping elements to enable these components to be machined on 5 sides.

The centering clamping mandrels, cylindrical have the following characteristics:

- Clamping stroke max. 0.7 mm

- Two versions - for press-in or screw-in

- Made of stainless steel or free-cutting steel

- Clamping body can be machined very easily (for adaptation to bore diameter)

This article 23340.0512 - Centering Clamping Mandrels cylindrical / press-fit (d1: 12 mm) is one variant of the article group Centering Clamping Mandrels cylindrical (EH 23340.)

More details

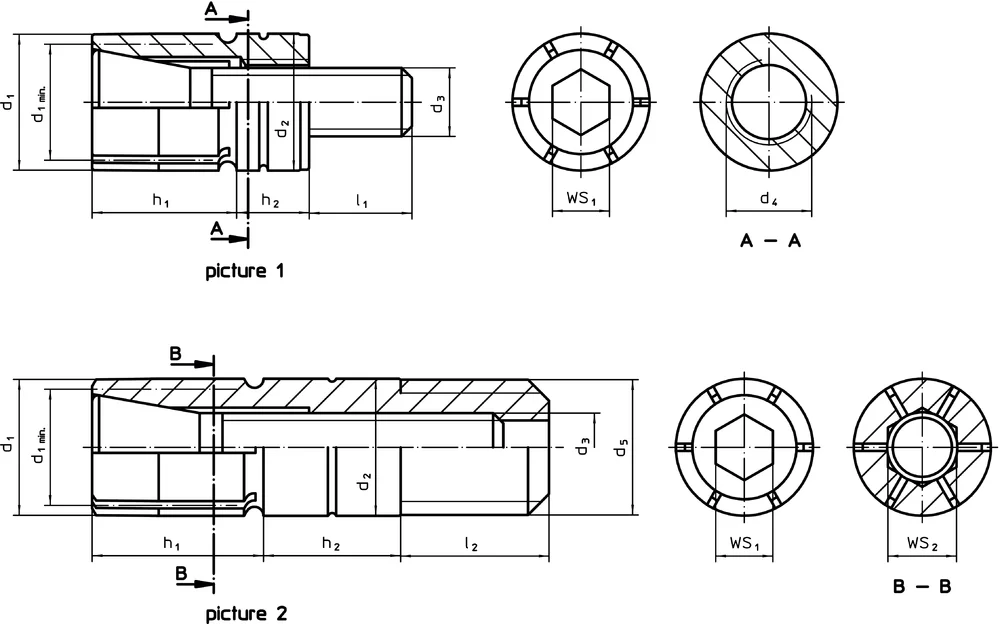

- press-fit – picture 1, Free cutting steel

- d1: 12 mm

- d1 min.: 10.5 mm

- d2 -0.025: 12 mm

- d3: M6

- d4: M8

- h1: 12.7 mm

- h2: 6.35 mm

- l1: 11.1 mm

- WS WS1: 5 mm

- Number of segments: 6

- Clamping force max.: 8.5 kN

- Tightening torque max.: 17 Nm

- Location hole H7: 12 mm

- Weight: 17 g

Material

Body

- Free cutting steel

Clamping screw

- Steel

Assembly

The centering clamping mandrel can be adjusted to the respective diameter by turning or milling.

Picture 1 - Mounting in bore hole or socket.

Thread for clamping screw required.

Picture 2 – Mounting in thread.

Clamping screw for the mounting.

Remove from body.

Srew-in centering clamping elements and tighten using the wrench size (WS2).

Operation

It is operated using the conical clamping screw (WS1). This expands the body by up to 0.7 mm.

RoHS compliant

Compliant according to Directive 2011/65/EU and Directive 2015/863.

Does not contain SVHC substances

No SVHC substances with more than 0.1% w/w contained - SVHC list [REACH] as of 27.06.2024.

Does not contain Proposition 65 substances

No Proposition 65 substances included.

https://www.P65Warnings.ca.gov/

Free from Conflict Minerals

This product does not contain any substances designated as "conflict minerals" such as tantalum, tin, gold or tungsten from the Democratic Republic of Congo or adjacent countries.

Contacts

Contact Standard Parts Contact Workholding Systems Contact Aviation Products RepresentativeContact Form

Information Material

Information material Standard Parts Information material Workholding Systems Information material Aviation ProductsNews

Have a look to our current new parts:

Threaded Lifting Pins with handle Bedding Supports Spring Push Plungers Accessories for spring plungers Index Plungers / Index Bolts Damping Elements Hinges Knurled Nuts / Knurled Thumb Screws