-

Produse

Grupe principale

- Organe de maşini şi dispozitive de fixare

- Elemente de fixare

- Elemente de funcţionare

- Organe de maşini

- Sisteme cu fantă T

- Sistem cu găuri

- Produse standard pentru sisteme de fixare modulare

- Bride de fixare multiple

- Menghine multiple

- Elemente de bază

- Sisteme cu montaj de precizie

Noutăți- Şuruburi de presiune cu bilă şi locaş hexagonal

- Şuruburi de presiune cu bilă şi fantă

- Şuruburi de presiune cu hexagon interior

- Şuruburi de presiune varianta netedă, cu guler şi bilă

- Opritoare cu indexare mini

- Opritoare cu indexare compacte cu guler hexagonal

- Opritoare cu indexare compacte cu guler hexagonal şi mecanism de fixare

- Ştifturi ridicătoare cu filet autoblocant

- Ştifturi ridicătoare cu filet autoblocant, pentru găuri de centrare conform DIN 332

- Ştifturi ridicătoare cu filet autoblocant, cu cheie de tachelaj rotativă

- Ştifturi ridicătoare cu filet autoblocant - INCH

- Ştifturi ridicătoare cu filet autoblocant, cu cheie de tachelaj rotativă - INCH

- Ştifturi cu bile pentru filet autoblocant

- Ştifturi cu bile pentru filet autoblocant, cu rulment axial

- Cabluri de fixare pentru ştifturi cu bile pentru filet

- Expander® Cepuri de etanşare corp şi bilă din oţel inoxidabil

- Bride de fixare pe verticală rotativă, mărimea 25

- Bride de fixare pe verticală rotativă, mărimea 60

- Inele de poziţionare pentru bride rapide de fixare

- Cilindrii de ajustare a înălţimii

- Mânere tip U

- Mânere tip U montaj frontal

- Mânere tip U cu saibă

- Mânere tip U

Informații suplimentare:Domenii de aplicare- Construcții / amenajare grădini și terenuri

- Montarea parchetului

- Lucrări de montare a sticlei / construcția ferestrelor

- Agricultură / silvicultură

- Industria de prelucrare a metalelor

- Tapiţerie / Pielari

- Lucrări de tâmplărie

- Lucrări la instalațiile sanitare

- Întreținere / reparații

- Lucrări de dulgherie / montare acoperișuri

Grup de produse- Locksmith's Hammers

- Ciocan Combinat

- Unelte forestiere

- Accesorii

- Pachete promoţionale

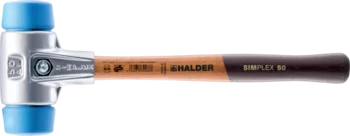

- Ciocane SIMPLEX cu capete moi, carcasă din fontă

- Ciocane SIMPLEX cu capete moi, carcasă din fontă tratată

- Ciocane SIMPLEX cu capete moi, carcasă din aliaj uşor

- Ciocane SIMPLEX cu capete moi, carcasă din fontă, cu "Stand-Up"

- SIMPLEX cu capete moi, carcasă din fontă, 50:40

- Ciocane SIMPLEX cu capete moi, carcasa din aluminiu, 50:40

- Cicane cu capete moi SIMPLEX, carcasă din fontă, mâner scurt

- Cicane cu capete moi SIMPLEX, carcasă din fontă, cu mâner scurt cu "Stand-Up"

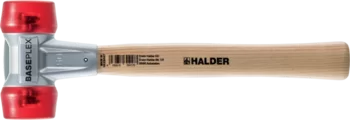

- Ciocane BASEPLEX cu capete moi

- Ciocane de forjă SIMPLEX , carcasă din fontă

- Ciocane SIMPLEX de forjă, carcasă din oţel turnat armat

- Ciocane de forjă SIMPLEX , carcasă din fontă, cu "Stand-Up"

- Ciocane SUPERCRAFT cu capete moi

- Ciocan BLACKCRAFT cu capete moi

- Ciocan SECURAL cu capete moi

- Ciocane de forjă SUPERCRAFT

Noutăți- SIMPLEX Plus Box Starter Kit SIMPLEX soft-face mallet D60, rubber composition with "stand-up" / superplastic as well as one TPE-soft and one TPE-mid insert plus bottle opener

- SIMPLEX Plus Box Starter Kit SIMPLEX soft-face mallet D80, rubber composition with "stand-up" / superplastic as well as one TPE-soft and one TPE-mid insert plus bottle opener

- SIMPLEX Promotional Box Automotive SIMPLEX soft-face mallet D40, copper / soft metal plus puncher

- BLACKCRAFT Promotional Box Automotive BLACKCRAFT soft-face mallet D60 plus Magnetic Holder

- Promotional Box Dreamteam Door and Window Construction SIMPLEX soft-face mallet 50:40, TPE-soft / TPE-mid and SECURAL plus soft-face mallet

- Ciocane SIMPLEX cu capete moi, de la 50 la 40 TPE-moale / TPE-mediu; cu carcasă din fontă şi coadă din lemn de înaltă calitate

- Ciocane SIMPLEX cu capete moi, de la 50 la 40 TPE-moale / TPE-mediu; cu carcasă din aluminiu şi mâner din lemn de înaltă calitate

- Inserţii SIMPLEX, 50 la 40 TPE-mediu, gri

- Service

- Ştiri

- Companie

- Contact

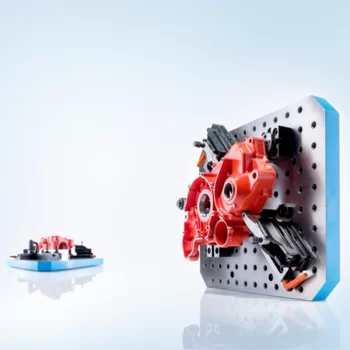

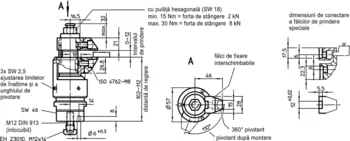

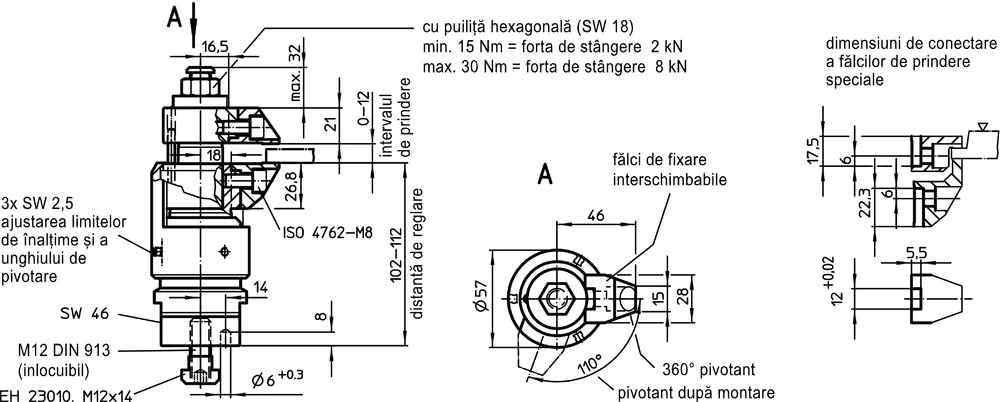

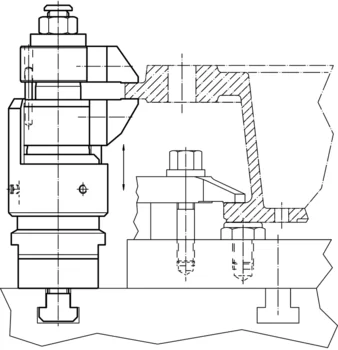

Cleme pivotante acţiune combinată de prindere şi fixare M 12

EH 23320.

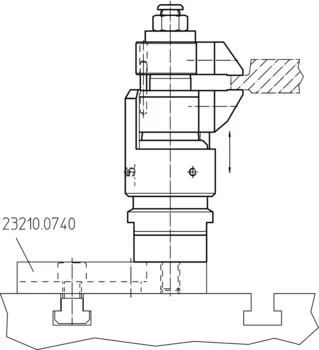

Clema pivotantă este folosită pentru prinderea şi susţinerea punctelor de prindere la componente.

Beneficiile clemei pivotante sunt:

- În timpul prelucrării nu apar vibraţii

- Suprafaţă cu striaţii, pentru prinderea şi fixarea sigură a pieselor la prelucrare

- Prinderea pieselor mari şi prefabricatelor fără deformaţii.

Cautarea dvs. a dat 1 rezultate

[g]

[g]Mai multe detalii

Material

Corp ajustabil

- Aluminiu anodizat roşu

Corp

- Oţel cementat, nitrurat, tratat cu fosfat de magneziu şi şlefuit

Bacuri de fixare

- Oţel cementat, nitrurat, tratat cu fosfat de magneziu

Note

Pentru o funcţionare sigură, gaura filetată trebuie să fie închisă, ex. setul de filete M 12 x 10.

Pentru soluţii specifice de prindere, bacurile standard livrate pot fi schimbate sau înlocuite (vezi desen din catalog: şurubul ISO 4762 - M 8 - 12.9, M max. = 43 Nm.).

Referinţe

Posibilitate de livrare cu suport 23470.0250 sau cu placă de susţinere pentru cleme model 23210.0740.

Asamblare

- Montaţi clema pivotantă (cu filet M 12) pe dispozitiv cu o cheie (SW 46).

- Ajustaţi limitatorul de înălţime şi zona de rotaţie cu manşonul roşu şi fixaţi cu şuruburi (3 x SW 2,5). La stabilirea limitei de înălţime, luaţi în considerare toleranţa piesei.

Operaţii

- Împingeţi clema în jos.

- Pivotaţi bacurile de prindere cât de mult posibil. Bacul intră în contact cu partea de jos a piesei cu ajutorul forţei arcului.

- Strângeţi clema cu o piuliţa hexagonală (SW 18) până la o forţa min. de 15 Nm sau maxim de 30 Nm. În procesul de fixare, piesa de lucru este fixată şi simultan susţinută.

- Eliberarea se face în ordine inversă.

Accesorii

Ca şi accesorii, vă oferim şi bacuri de prindere cu o cursa mărită, se referă la mărimile de la 23320.0050-0058, la fel şi pentru bacurile pivotante 23320,0148-,0156.

Produse asociate

Conform RoHS

Conţine plumb – conform excepţiilor 6a / 6b / 6c.

Conţine substanţe SVHC >0,1% w/w

Conţine plumb - lista SVHC [REACH] din 23.01.2024

Conţine substanşe din Declaraţia 65

Prin expunere plumbul poate provoca cancer şi afectarea fertilitaţii

https://www.P65Warnings.ca.gov/

Nu conţine Minerale de conflict

Acest produs nu conţine substanţe desemnate drept „minerale de conflict” precum tantalul, staniul, aurul sau wolfram din Republica Democratică Congo sau din ţările adiacente.

Care este scopul utilizării clemelor pivotante?

Clemele pivotante previn apariţia vibraţiilor şi au ca rezuliat o calitate mai bună a prelucrării. Pot fi utilizate ca şi bride clasice de fixare şi împreuna cu elementele de sustinere devine un dispozitiv de fixare cu 3 puncte de prindere. Acest lucru nu mai permite o încarcare suplimentară de forţe în piesa de prelucrat.

Care sunt beneficiile utilizării de cleme pivotante în producţie?

Clemele pivotante permit adăugarea unui punct de fixare suplimentar în timpul primelor operaţii de prelucrare, prevenind apariţia vibraţiilor. Acest lucru ajuta la îmbunătăţirea calităţii suprafeţei prelucrate şi prelungeste viaţa sculelor. Acum este garantată o prelucrare sigură şi eficientă.

Care este diferenţa dintre clemele pivotante roşii si cele albastre?

Clemele pivotante roşii fixează şi blochează piesa intr-o singură operaţiune. Cele albastre permit fixarea şi blocarea piesei in operaţii separate. Sunt folosite în general la piese de prelucrat cu pereţi subţiri sau instabile.

Care sunt avantajele clemelor pivotante faţă de elementele de suport?

Avantajul este că pe lăngă suportul clemei acestea fixază piesa şi de sus.

Care sunt beneficiile clemelor pivotante faţă de bridele clasice de fixare?

Forţa arcului cu care intră în contact clema este întodeauna aceaşi. Acest lucru ajută ca piesa saă nu se îndoaie şi nu mai sunt necesare elemente auxiliare de suport. de asemenea sunt foarte compacte şiuşor de utilizat. Cu siguraţă ca aceastea fac ca dispozitivul de fixare să sie mult mai stabil.

Aceste cleme asigură o repetabilitate bună?

Aceste cleme poti fi adaptate la un unghi de pivotare dorit şi la o înalţime dorită cu ajutorul corpului colorat.

Ce trebuie sa luăm în considerare când utilzăm aceste cleme?

Trebuie luat în considerare momentl maxim de fixare permis când fixaţi cu aceste cleme. Aceste informaţii sunt marcate pe clemă sau le puteţi găsii în catalog. Aveţi mare grijă şi la nivelul de ulei din emulsia de răcire, acesta poate să ducă la aparăţia ruginei înpiesele interne ale clemei pivotante.

Cât de mare este forţa exercitată pe piesă de către bacul inferior al clemei?

Forţa de contact ale clemelor pivotante 23320.0008 şi 23320.0010 este între 18 şi 42 N. Pentru 23320.0012 şi 23320.0014 este între 19 şi 27 N, iar pentru 23320.0016 este de aprox. 73 şi 99 N.

Este posibil să folosim bacuri mai lungi pentru aceste cleme, dacă da, care este lungimea maximă?

Da, se pot folosi bacuri speciale.Dar, lungimea maximă este limitată în funcţie de mai multe variabile, formă, material. Bacuri cu lungime de 73 mm au fost deja utilizate. oricum, o funcţionare corectă nu se poate garanta când utilizaţi bacuri speciale. Clema albastră este mai puternică, acest lucru o recomandă când sunt necesare bacuri speciale. este important ca şuruburile de fixare a bacurilor să fie montate în clema cu min. 10 mm bacul de sus şi 9 mm bacul de jos. Vă rugăm de asemenea să respectaţi instrucţiunile de asamblare pe care le găsiţi in catalog.

Ce operaţii de mentenaţă / reparaţii sunt necesare la aceste cleme ?

Nu sunt necesare operaţii de mentenanţă. Recomandăm totuşi ca o verificare vizuală să fie facută din când în când .

Ce putem face când aceste cleme se deteriorează?

În majoritatea cazurilor, reparaţia lor este posibilă. pentru a programa o reparaţie, vă rugăm sa contactaţi cel mai apropiat reprezentant.

Se pot uriliza aceste cleme în sistemele Halder V70 cu canale T?

Clemele pivotante poti fi utilizate în întreaga gama de sisteme modulare. puteţi alege o variantă din gama - M12 sau M16. Modelul cu flanţă este de asemenea o variantă bună. Toate opţiunile disponibile le puteţi vedea în catalog.

Contacts

Persoane de contact Piese standard Persoane de contact Sisteme de fixare Persoane de contact Produse pentru aviație ReprezentanțăContact Form

Information Material

Informații despre produs Elemente standardizate Informații Sisteme de fixare Informații Produse pentru industria aviaticăNews

Have a look to our current new parts:

Locating Pins Eccentric Clamping Clamps Pitbull® Clamps Centering Clamping Mandrels