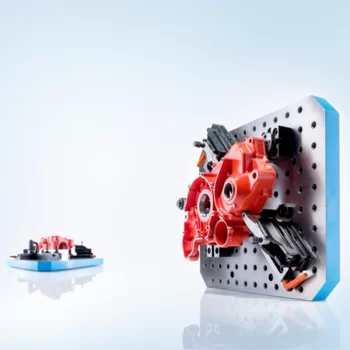

“The quick and easy positioning of a workpiece with our locating pins merely requires two bore holes with the matching fit size. No matter which version they choose - users will only have to insert a cylindrical / spherical and a flat-faced version into the machine table / the fixture with a spacing that matches the distance of the two bore holes. The user will then proceed to slip the workpiece with the first bore hole over the round pin before flipping it down into the second bore hole using the flat-faced pin. The flat-faced side makes it possible to compensate for tolerances and to position the workpiece with no effort, says Bernd Janner, Sales Manager at Erwin Halder KG, explaining the assembly of the locating pins. What is more, the cylindrical locating pins can also be used as a seating element, a locating element or a stop.

The locating pins according to DIN 6321 are made from hardened and ground tool steel and can be purchased in standard diameters ranging from 6 to 25 mm. Even more security can be achieved with the locating pins with bore hole made from hardened, blackened, and ground case-hardened steel. They can be attached from the top or the bottom with a screw. This ensures that the pins will not be pulled out of the machine table / the fixture along with the workpiece. Similar to DIN 6321, they are also available in diameters of 6 to 25 mm.

“Those who wish to insert the workpieces with even greater ease might want to consider the locating pins with ball end. The ball shape reliably prevents the workpieces from becoming jammed”, adds Bernd Janner. Available with and without a step depending on the version, the locating pins with ball end come in diameters ranging from 7 to 50 mm. Users can choose between hardened, blackened, and ground tool steel and ground / surface-hardened stainless steel (1.4305). The stainless steel version is particularly well-suited for locating pins that remain in the machine.

The vast catalogue selection of different versions and sizes ensures that users will find the right locating pin for (nearly) every application. Better still, if unable to find the right product right away, users can order custom versions that Halder will design and manufacture on request.